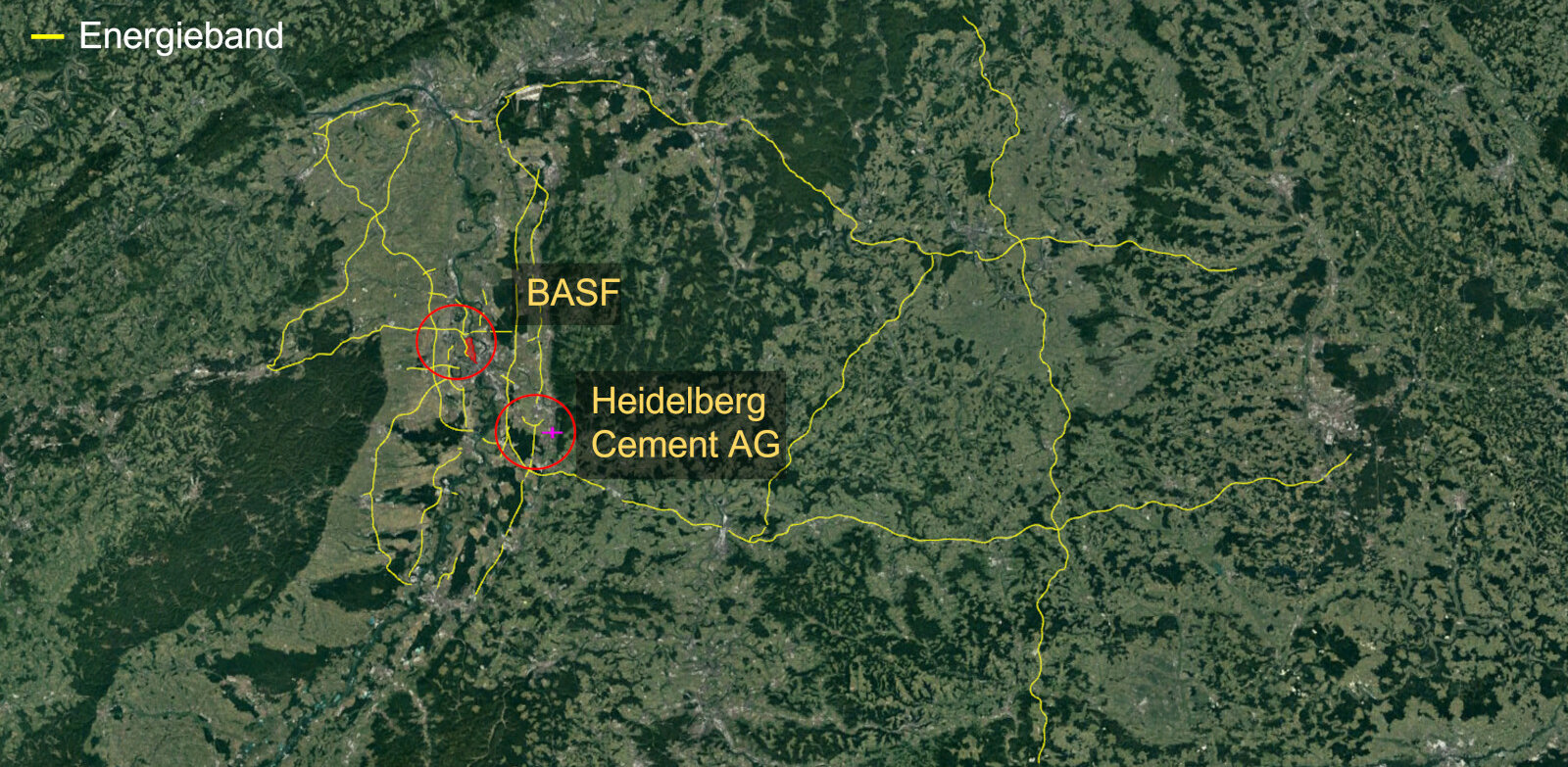

Theoretical Industry Case Study BASF and HeidelbergCement Outside-in Case Study

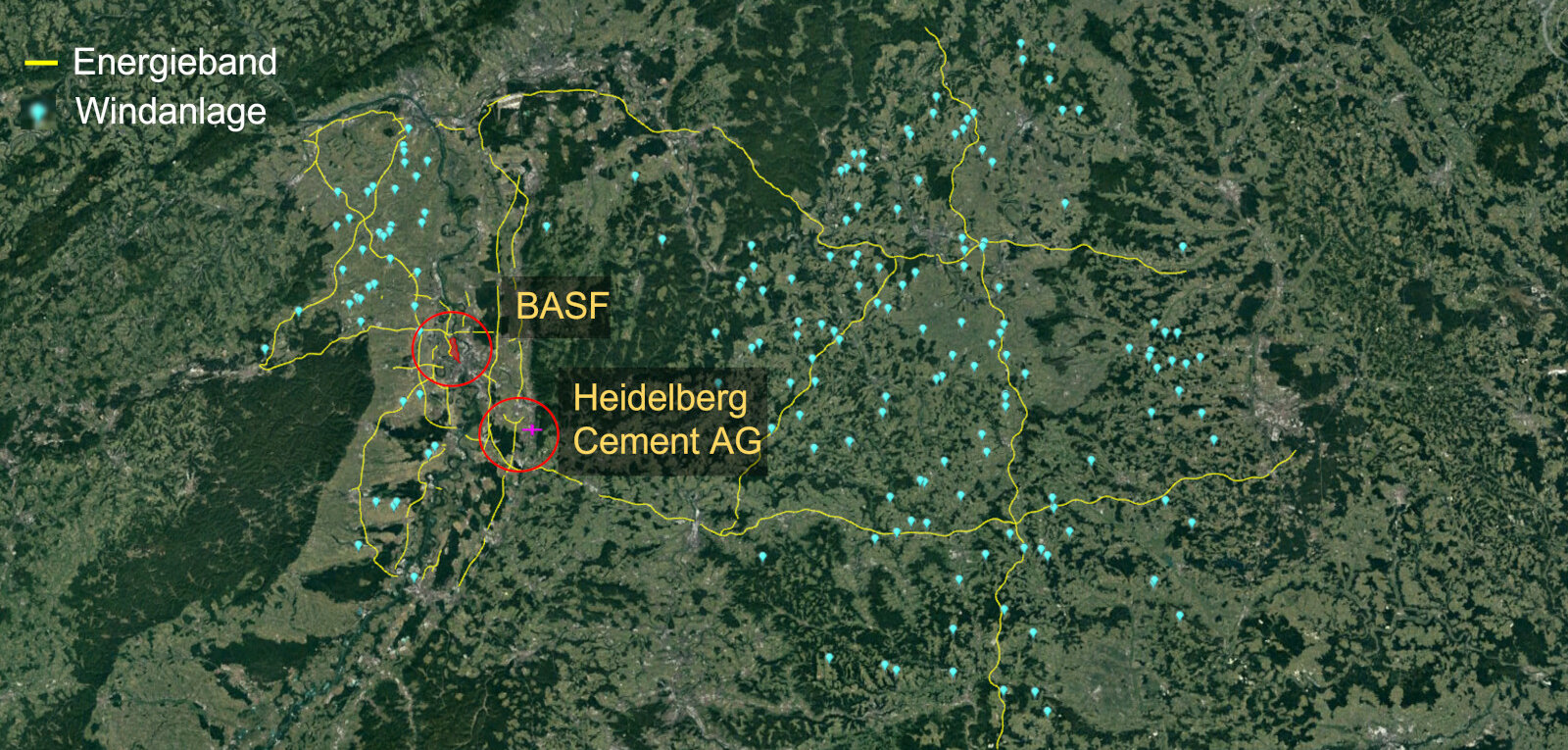

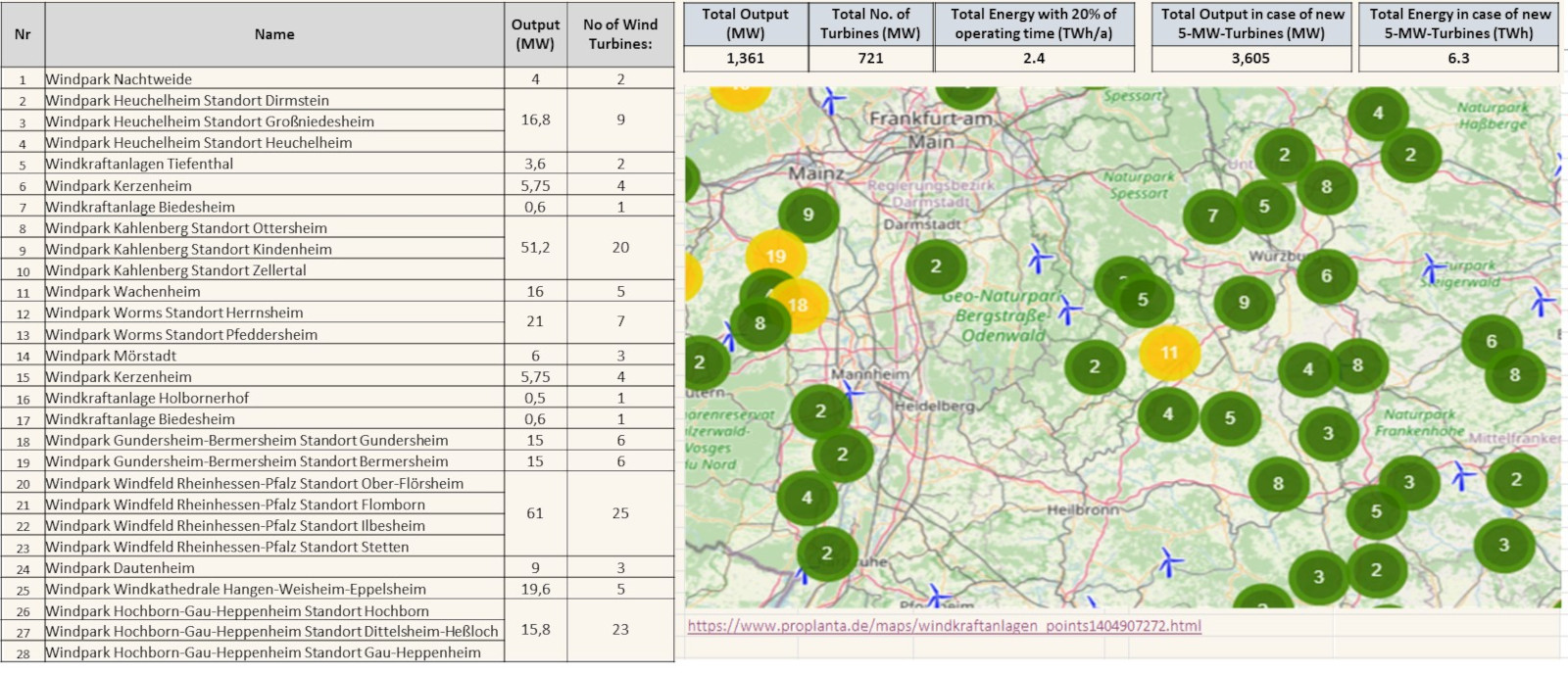

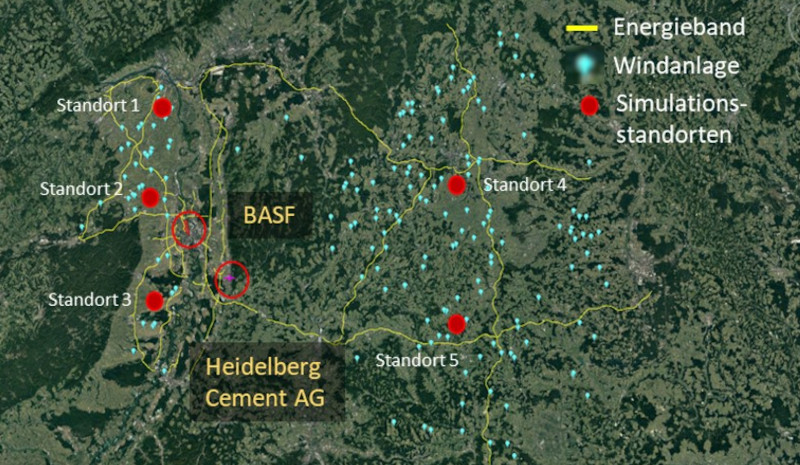

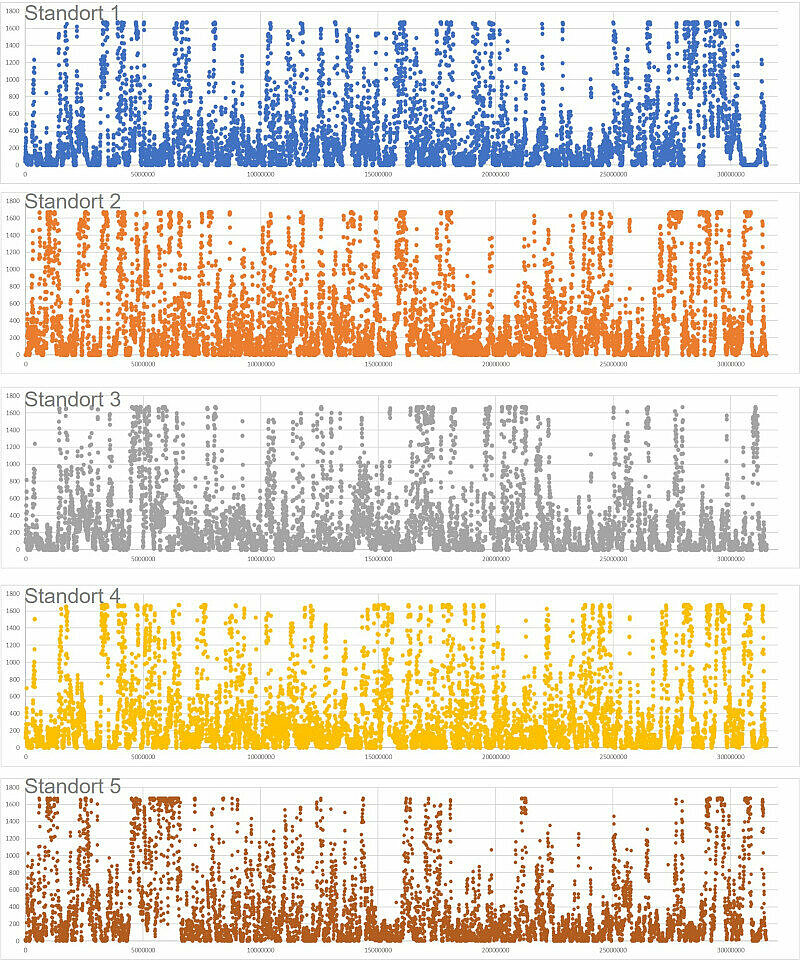

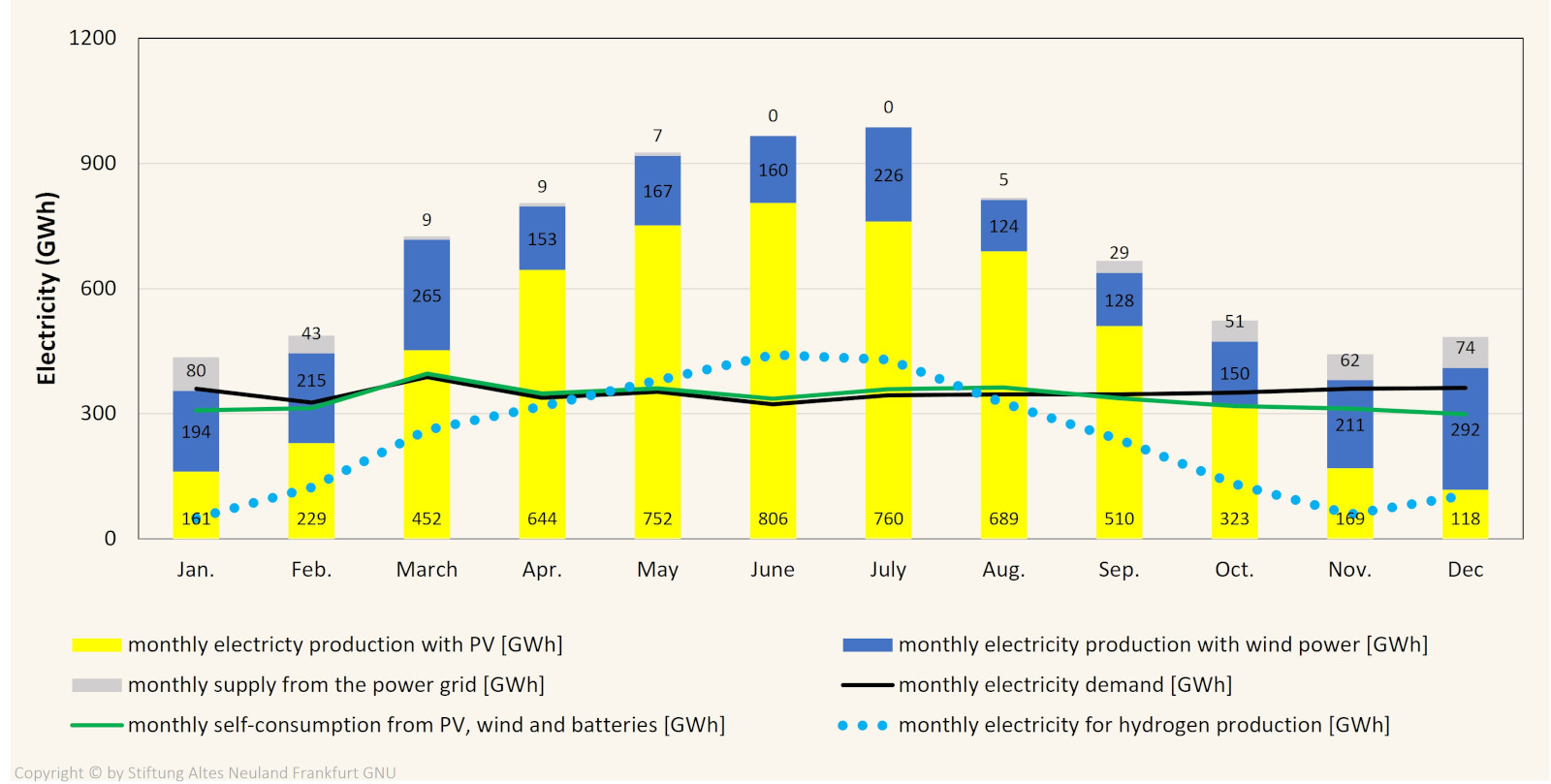

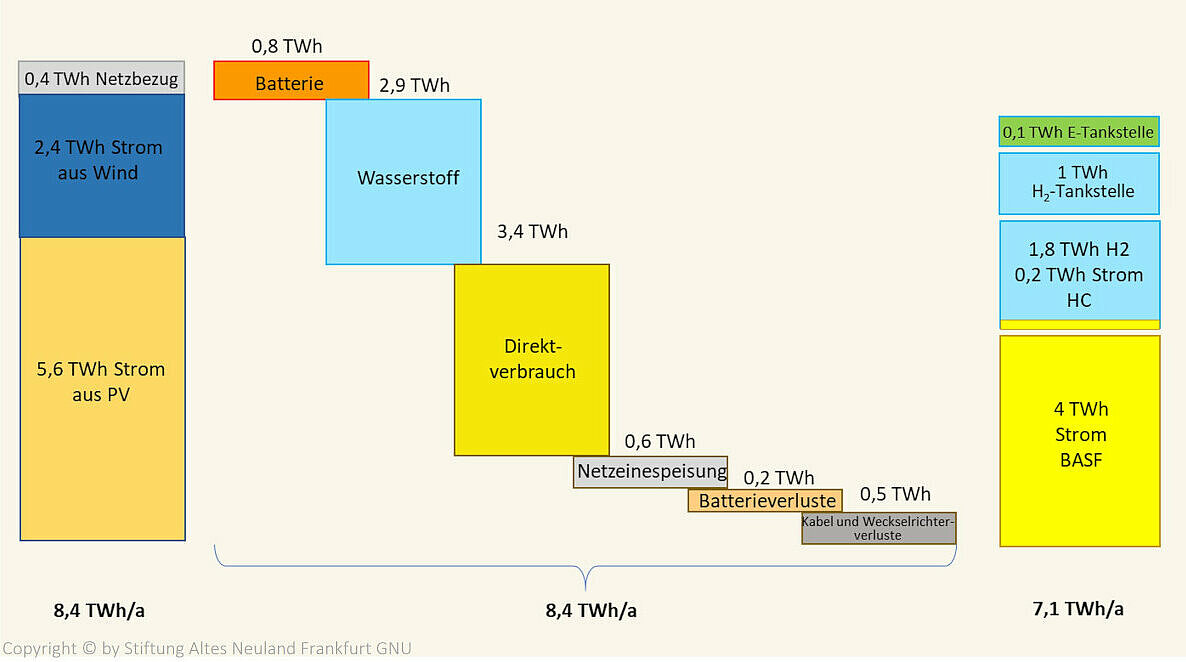

The two companies were chosen, assuming that they are prototypical for a purely theoretical set of simulations (1) because they are relatively close to each other, so that they can potentially realize economies of scale and (2) because they are located in a region with relatively high solar and wind resources.

Both companies have already converted large parts of their energy supply to renewable energies and are aiming for CO2 neutrality in the future.

The case study has been prepared without the participation of the companies and is only intended to show theoretically and by way of example how the supply of large industrial sites with decentrally generated renewable energies could look in 2050.

All data and information on the companies are estimates made on the basis of publicly available information.